The Fascination and Restoration of Wooden Rowing Machines

Charm and History of Wooden Rowing Machines

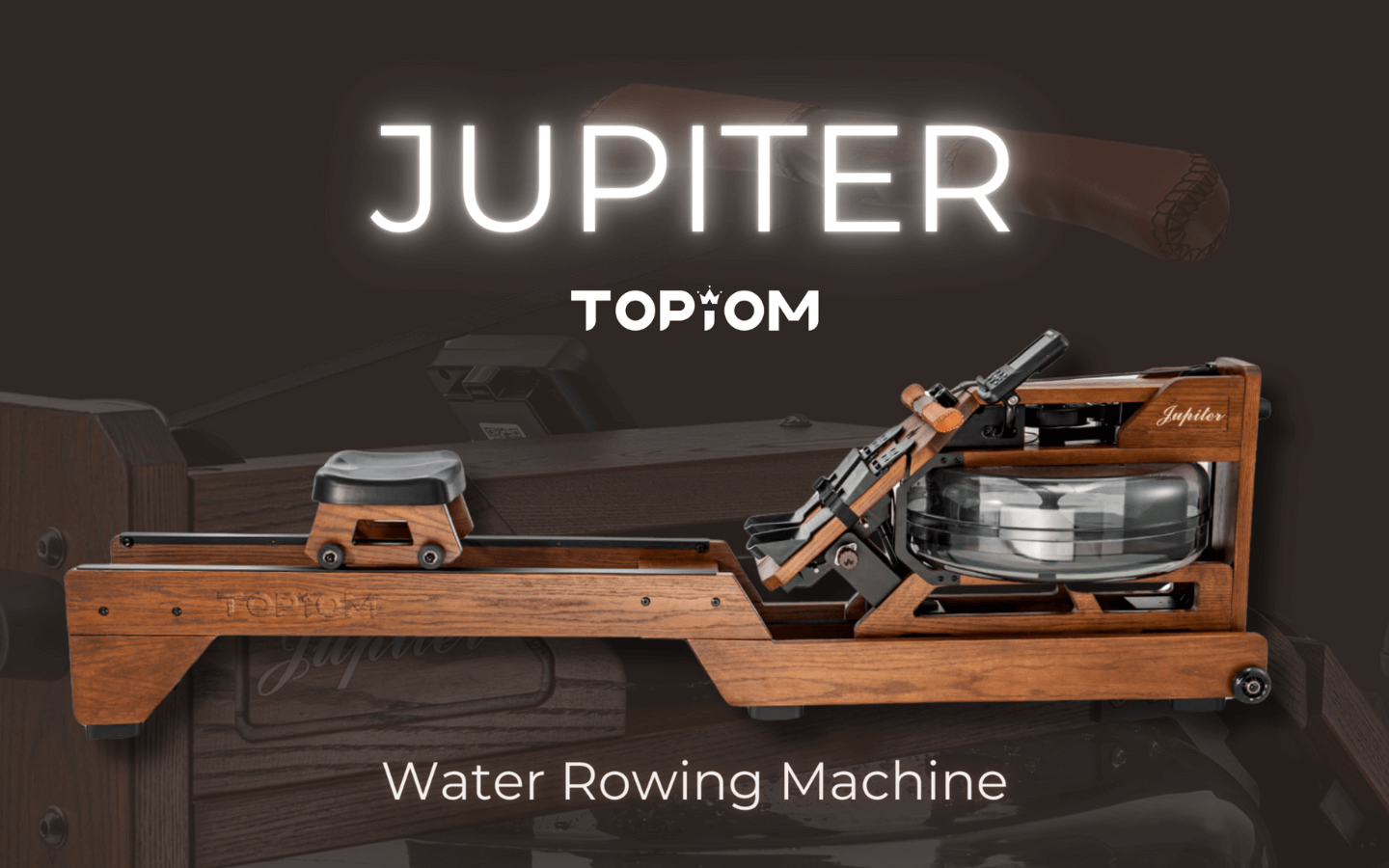

Embark on a journey into the allure of wooden rowing machines, where craftsmanship meets functionality. These timeless pieces of fitness equipment have a rich history, reflecting both the artistry of their construction and the cultural significance of rowing. Delve into the captivating narrative of how wooden rowing machines have evolved, blending aesthetics with purpose to create an enduring symbol of elegance.

The Intriguing and Beneficial Undertaking of Restoring Aging Rowing Machines

Discover the enchanting world of restoring aging rowing machines, a venture that seamlessly combines fascination with practicality. Breathing new life into these vintage pieces not only preserves their historical value but also offers a rewarding and enjoyable project. Uncover the reasons why restoring aged rowing machines proves to be both a captivating hobby and a beneficial endeavor, fostering a connection between the past and present.

Assessing the Condition of a Rowing Machine for Optimal Performance

Examining Wear and Tear on Wooden Components

To ensure the longevity of your rowing machine, regularly inspect its wooden elements for signs of wear and potential cracks. Focus on areas prone to stress, such as the seat and handles. Prompt identification and addressing of any wear will not only prolong the machine’s lifespan but also contribute to a smoother and safer rowing experience.

Verifying the Mechanical Operations

A crucial aspect of evaluating a rowing machine involves a thorough check of its mechanical components. Assess the functionality of the resistance mechanism, monitor the smoothness of the sliding seat, and inspect the integrity of the pulley system. A well-maintained mechanical setup guarantees a consistent and effective workout. Any anomalies should be addressed promptly to avoid further damage.

Determine the Need for Component Replacement

In the assessment process, carefully consider whether certain parts require replacement. Evaluate the condition of belts, cables, and any other components subject to wear. Timely replacement of worn-out parts is essential for preventing breakdowns and ensuring the rowing machine’s continued reliability. Regularly assessing and replacing components as needed will uphold the machine’s performance standards, providing a reliable tool for your fitness journey.

Preparation Essentials for Rowing Machine Maintenance

Gathering Necessary Tools and Materials

Before diving into rowing machine maintenance, ensure you have all the required tools and materials at your disposal. Collect items such as screwdrivers, lubricants, and replacement parts to streamline the repair process. Having everything organized and within reach will save time and make the maintenance procedure more efficient.

Cleaning the Surface of the Rowing Machine

A crucial step in preparation is to thoroughly clean the surface of the rowing machine. Remove dust, debris, and any accumulated grime from the exterior. A clean machine not only promotes a more hygienic workout environment but also ensures that the internal components function optimally. Regular cleaning extends the lifespan of the equipment and enhances the overall user experience.

Disassembling Parts for Repair or Replacement

To address any issues with the rowing machine, systematically disassemble components that require repair or replacement. Carefully identify and remove malfunctioning parts, making notes if necessary. This preparatory step lays the foundation for a focused and effective maintenance session, ensuring that the subsequent repairs are carried out seamlessly. Take the time to disassemble, assess, and prepare for a successful rowing machine restoration.

Revitalizing Wooden Surfaces: A Comprehensive Restoration Guide

Stripping Old Finishes and Smoothing Wood Surfaces

To breathe new life into wooden elements, start by removing old finishes and meticulously sanding the wood surface. This essential step not only prepares the wood for restoration but also ensures a clean canvas for subsequent treatments.

Mending Cracks and Damages

Addressing cracks and damages is pivotal in the wood restoration process. Employ specialized techniques and high-quality fillers to seamlessly repair any imperfections. This meticulous approach guarantees a sturdy and aesthetically pleasing outcome, preserving the natural beauty of the wood.

Applying Finishes and Safeguarding Wood Surfaces

Elevate the appearance of the wood by applying a suitable finish that complements its characteristics. Whether it’s a stain, varnish, or protective sealant, choose a product that enhances durability and brings out the wood’s inherent charm. This final touch not only adds aesthetic appeal but also safeguards the restored wood surface for long-lasting beauty.

Optimal Performance: Maintenance Tips for Mechanical Components

Ensuring Smooth Operation through Lubrication of Moving Parts

Proper maintenance of mechanical components is essential for sustained performance. To keep machinery running smoothly, regular lubrication of moving parts is crucial. Applying high-quality lubricants to joints and bearings minimizes friction, reduces wear and tear, and extends the lifespan of the equipment. Incorporating a routine lubrication schedule is a simple yet effective way to enhance overall functionality.

Fine-Tuning Performance with Resistance System Adjustments

Achieving optimal performance involves fine-tuning the resistance system. Regular adjustments ensure that the machinery provides the desired level of resistance, creating a challenging yet safe workout environment. Whether it’s a hydraulic system or magnetic resistance, routine checks and adjustments guarantee a consistent and effective workout experience.

Preserving Longevity by Replacing Worn Belts or Cables

To maintain the integrity of the machine, it’s crucial to promptly replace worn-out belts or cables. Over time, these components may experience wear and tear, compromising the equipment’s efficiency and safety. Regular inspection and timely replacement of damaged belts or cables contribute to the longevity of the machinery, preventing potential hazards and ensuring a secure workout environment. Keep your equipment in peak condition through diligent attention to these maintenance practices.

Effective Care Strategies for Longevity

Regular Cleaning and Maintenance

To prevent wear and tear, establish a routine for cleaning your rowing machine. Wipe down surfaces, check for loose parts, and lubricate moving components as recommended by the manufacturer. Regular maintenance not only extends the lifespan of the machine but also ensures a smooth and safe workout experience.

Avoid Prolonged Exposure to Extreme Humidity or Dryness

Protect your rowing machine from environmental extremes. Prolonged exposure to high humidity or dry conditions can lead to rust, corrosion, and damage. Store your equipment in a moderate environment to safeguard its structural integrity.

Savor the Renewed Vitality Post-Repair

After any repairs or maintenance, relish the revitalized performance of your rowing machine. However, it’s essential to continue with consistent upkeep. Regular checks, even after repairs, help identify potential issues early, ensuring that your rowing machine remains a reliable fitness companion for the long term.